caTEGORIES

Tags

Step-by-Step Guide to Extracting Through Bolts for Replacement

Posted: May 29, 2025

Categories: News

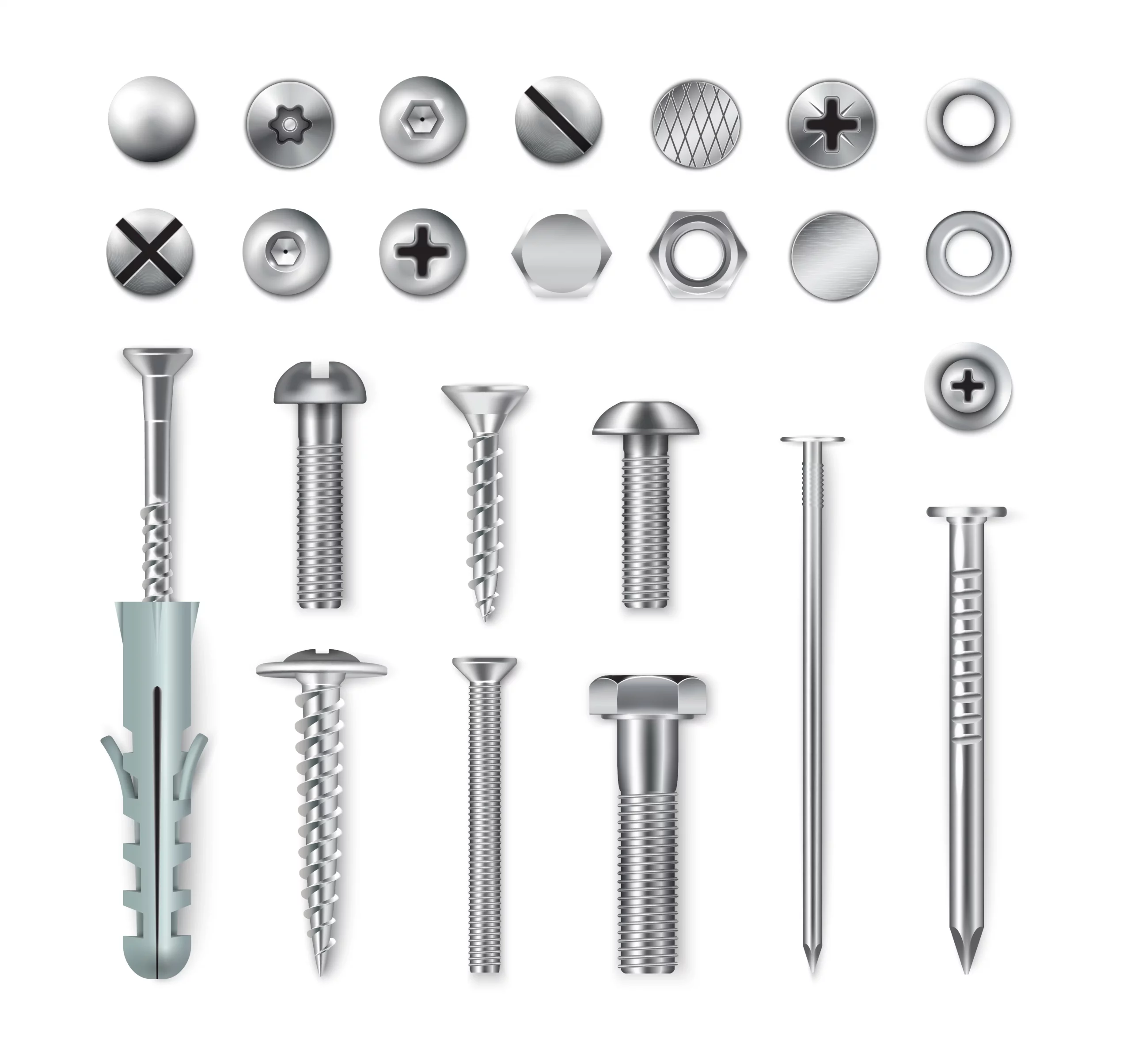

Through bolts (also called anchor fasteners or expansion fasteners) are vital components in building and mechanical applications. They firmly connect heavy objects to concrete, brickwork, or other solid surfaces. However, removing them—particularly when rusted or broken—demands proper techniques and equipment to maintain structural safety. This manual explains through bolt functions, safe removal procedures, common replacement challenges, and installation best practices. We feature QEWIT‘s premium bolt solutions, offering dependable fastening options for both commercial and domestic projects. Whether handling seized bolts or selecting new ones, this guide delivers actionable recommendations.

What Are Through Bolts and Their Applications?

What Are Through Bolts?

QEWIT produces top-tier through bolts. These are made from materials like carbon steel, stainless steel, brass, or alloys. The materials ensure longevity and corrosion resistance. QEWIT enforces strict quality controls. They provide test certificates to confirm reliability. Their bolts come in various sizes and finishes to suit different needs. Since 2004, QEWIT has focused on premium, consistent products. Learn more about their through bolts for your construction projects.

Common Uses of Through Bolts in Construction and Engineering

Through bolts are widely used in construction and engineering due to their reliability and strength. They are often employed for fixing heavy machinery, structural supports, railings, and brackets to concrete surfaces. Their ability to withstand significant loads makes them indispensable in both residential and industrial settings. Additionally, they are commonly used in projects requiring high levels of safety and durability.

Key Features of QEWIT Through Bolts

The through bolts offered by QEWIT. stand out for their exceptional quality and performance. These bolts are manufactured using materials like carbon steel, stainless steel, brass, or alloys, ensuring durability and resistance to corrosion. With stringent quality control measures in place, QEWIT provides test certificates for its products to guarantee reliability. Their through bolts are available in various sizes and finishes to meet diverse application needs. QEWIT has been devoting itself to producing and trading premium and consistent quality products since its establishment in 2004.

Tools and Preparations Needed for Bolt Extraction

Essential Tools for Removing Through Bolts

Extracting through bolts requires specific tools for safety and efficiency.

Wrenches and Socket Sets

A reliable wrench or socket set is crucial. It grips the bolt head securely during removal. Depending on the bolt size, use adjustable wrenches or specialized sockets for a precise fit.

Lubricants and Penetrating Oils

Penetrating oils, like WD-40, loosen rusted or stuck bolts. They reduce thread friction. Applying these before removal eases the process significantly.

Safety Equipment and Precautions

Safety is paramount when using tools. Wear gloves, safety goggles, and steel-toed boots. These protect against slipping tools or falling debris.

Preparing the Work Area for Safe Extraction

Clear the work area of obstacles before starting. Ensure adequate lighting for visibility. Keep tools organized and accessible. This minimizes movement during extraction.

Step-by-Step Process to Remove a Through Bolt

Assessing the Condition of the Bolt and Surrounding Material

Inspect the bolt for corrosion, wear, or damage. These can complicate removal. Check the surrounding material for cracks or weaknesses. This ensures structural integrity during extraction.

Loosening the Bolt with Manual or Powered Tools

Using Torque Wrenches for Controlled Removal

A torque wrench applies controlled force. It loosens bolts without damage. Adjust the torque to match the bolt’s specifications for best results.

Applying Lubricants to Ease Stubborn Bolts

For resistant bolts, apply lubricant to the threads. Let it penetrate. Then retry loosening with a wrench or socket set.

Extracting a Broken or Damaged Bolt

Drilling Techniques for Broken Bolts

If a bolt breaks, drilling is often needed. Use a drill bit slightly smaller than the bolt’s diameter. Create a pilot hole in the center. Then use an extractor tool designed for broken fasteners.

Utilizing QEWIT Tools for Efficient Removal

QEWIT offers specialized extraction tools. These minimize damage to surrounding materials. With over 30,000 product lines, they provide tailored solutions. Their tools undergo rigorous quality checks. This ensures reliability in tough conditions.

Challenges in Replacing Shield Anchors and How to Overcome Them

Common Issues When Removing Shield Anchors

Corrosion and rust are frequent problems. Moisture and environmental exposure degrade metal over time. This makes anchors hard to remove. Corrosion increases thread friction. Lubricants can help loosen rusted parts. Severe corrosion may require drilling.

Tight or hard-to-reach spaces pose another challenge. Limited access complicates tool positioning. Deeply embedded anchors also require special techniques. These prevent damage to surrounding materials.

Compact tools, like angled wrenches or socket extensions, are useful. For embedded anchors, use a drill with an extractor attachment. This ensures precise removal.

Solutions Provided by QEWIT Products

QEWIT offers over 30,000 product lines. Their tools and fasteners address these issues efficiently. Made from stainless steel or alloys, their products resist harsh conditions. Rigorous quality assurance ensures reliability. Explore QEWIT’s specialized fasteners for shield anchor removal.

Selecting Replacement Bolts After Extraction

Choosing the Right Type of Replacement Bolts Based on Application Needs

Selecting a suitable replacement bolt is vital. Consider load requirements, environmental conditions, and material compatibility.

Comparing Material Strengths and Durability Options

Evaluate the material’s durability and strength. Stainless steel bolts resist corrosion. They suit outdoor or marine settings. High-tensile steel bolts handle heavy loads. They are ideal for demanding applications.

QEWIT offers bolts in carbon steel, brass, stainless steel, and alloys. Each undergoes strict testing to meet global standards.

Recommendations for QEWIT High-Performance Bolts & Nuts

QEWIT’s high-performance bolts meet DIN 933 and DIN 931 standards. They come in finishes like zinc plating or hot-dipped galvanization. These enhance corrosion resistance. QEWIT also provides custom non-standard fasteners for specific needs.

Best Practices for Installing New Through Bolts or Shield Anchors

Ensuring Proper Alignment During Installation

Alignment is critical during installation. Misalignment weakens the connection. It can cause early failure. Use tools like laser guides or spirit levels. Verify component positioning before securing the bolt. This reduces stress and ensures even load distribution.

Torque Guidelines for Secure Fastening

Correct torque ensures a secure fit. Over-tightening can damage components. Use a torque wrench for consistent force. Follow manufacturer torque recommendations. These vary by bolt size and material. QEWIT provides detailed installation guides with their products.

Maintenance Tips to Extend the Life of Installed Bolts

Regular maintenance extends bolt lifespan. Inspect for wear, rust, or stress periodically. Apply protective coatings like zinc plating. These resist environmental damage. Use nylon insert nuts to prevent loosening from vibration. QEWIT’s catalog includes these features.

FAQs:

Q1: What type of replacement bolt should I use after removing a shield anchor?

A: It depends on the application. Stainless steel bolts resist corrosion. High-tensile steel suits heavy-duty tasks.

Q2: How do I stop new bolts from loosening?

A: Use locking mechanisms like nylon insert nuts. Apply thread-locking compounds during installation.

Q3: Are there specific tools recommended for removing embedded shield anchors?

A: Yes, compact tools like angled wrenches or drills with extractor attachments are effective solutions provided by suppliers specializing in fastening systems.