caTEGORIES

Tags

When to Use Lock Nuts Instead of Standard Nuts in Your Projects

Posted: August 21, 2025

Categories: News

In fastening work, the little details decide whether a joint holds for years or starts rattling after a month. One of the common questions engineers, buyers, and site managers ask is—should I go for lock nuts or stick with standard nuts? Both look similar at first glance. Both hold bolts in place. But in the real world, the difference shows up when the equipment starts vibrating, temperatures swing, or maintenance crews get involved.

Let’s break it down in a way that isn’t just theory, but also drawn from shop-floor realities and the kind of supply experience we’ve built at Qewitco, where over 30,000 fastener product lines mean we’ve seen just about every application there is.

Understanding the Basics

What Are Standard Nuts?

A standard nut—think the everyday hex nut conforming to DIN 934—is the most widely used fastening partner for bolts and threaded rods. They’re simple, low-cost, and available in materials ranging from carbon steel to stainless steel. In our own range, we ship them bright zinc plated for corrosion resistance, or hot-dip galvanized for outdoor work.

They work well when:

The assembly isn’t exposed to constant vibration.

You need easy removal for regular maintenance.

Cost control is a big part of the project.

But—and it’s a big “but”—standard nuts rely entirely on the clamping force of the bolt to stay put. If that force loosens, so does the nut.

What Are Lock Nuts?

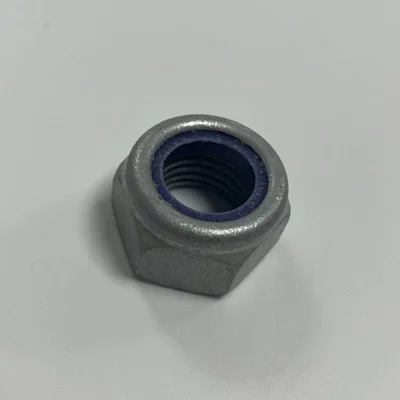

Lock nuts, on the other hand, are designed to resist loosening under vibration or torque. The “lock” can be mechanical, like a serrated flange (DIN 6923) that bites into the mating surface, or material-based, like a nylon insert (DIN 985 or DIN 982) that grips the bolt threads.

At Qewitco, we supply both:

Nylon insert lock nuts: Economical and widely used in automotive, machinery, and construction. The nylon collar slightly deforms over the threads, creating friction.

Metal lock nuts: Serrated flange types that act like a built-in washer, spreading the load and gripping hard against rotation.

When to Use Lock Nuts

For Vibrating or Moving Machinery

If you’ve ever been near a stamping press or conveyor line, you know vibration is a killer for unsecured fasteners. In these environments, a standard nut can loosen over time—even with a washer. Lock nuts hold their ground because their locking feature resists the “walk” caused by vibration.

We’ve had customers in rail maintenance who switched from standard nuts to DIN 985 nylon inserts on joint brackets. They cut downtime by half because crews weren’t constantly re-tightening.

In Safety-Critical or Load-Bearing Applications

Think about scaffolding joints, elevator guide rails, or bridge maintenance plates. In these cases, the cost of a fastener failing is more than just a repair—it’s a safety hazard. A lock nut gives that extra layer of security against accidental loosening.

One marine client of ours uses stainless steel serrated flange nuts on deck fittings. Saltwater spray, wave impact, constant motion—lock nuts handle all three without backing off.

In Environments with Thermal Expansion or Contraction

Metals expand and contract with temperature swings. If you’ve got an outdoor solar array in a desert climate, you might see 30°C temperature differences in a day. Standard nuts can lose preload as the metal “breathes.” Lock nuts keep more consistent tension through those cycles.

When to Stick with Standard Nuts

Static or Non-Vibration Applications

If your assembly is bolting a signpost to a static frame, or joining two panels in a non-moving structure, a standard nut is fine. It holds as well as a lock nut in static conditions—without the extra cost.

When Frequent Disassembly Is Required

Lock nuts, especially nylon insert types, can lose effectiveness if removed and reused repeatedly. If you’re working on test rigs or prototype assemblies that get stripped down every few weeks, standard nuts are easier on both the hardware and your hands.

Budget Constraints

Sometimes, the numbers decide for you. In large-scale projects—say, 50,000 units of a non-critical bracket—the extra few cents per lock nut add up. Standard nuts with proper tightening can still meet the need.

Alternative or Hybrid Solutions

Standard Nuts with Lock Washers or Thread-Locking Compound

Spring washers, serrated washers, or a dab of thread-locking fluid can improve resistance to loosening without fully switching to lock nuts. We’ve supplied complete kits with DIN 125A washers plus standard nuts for customers who want a mid-range solution.

Using Jam Nuts

A jam nut is simply a second, thinner nut tightened against the first. It’s old-school, but still used in certain agricultural machinery where lock nuts aren’t on hand.

Pros and Cons Summary

Lock Nuts

Pros:

Excellent resistance to vibration.

Added safety in critical applications.

Good for variable-temperature environments.

Cons:

Higher cost per unit.

Some types not reusable.

Can require more torque to install.

Standard Nuts

Pros:

Inexpensive and widely available.

Easy to install and remove.

Suitable for non-vibration applications.

Cons:

No built-in vibration resistance.

Preload loss more likely under movement or thermal cycling.

Conclusion and Recommendations

Choosing between lock nuts and standard nuts isn’t about one being “better” all the time—it’s about the right tool for the right job. At Qewitco, we’ve seen projects fail simply because the wrong nut was used in the wrong place. We’ve also seen budgets saved and timelines met by matching the fastener to the real-world demands of the application.

Automotive fasteners market projected at USD 22.72 billion in 2025 and growing at a 5.8% CAGR to 2033, selecting vibration- and thermal-resistant options like lock nuts can optimize long-term costs in dynamic environments.

If your project involves vibration, safety-critical loads, or thermal cycling, go lock nut. If it’s static, frequently disassembled, or budget-sensitive, a good-quality standard nut—especially with a washer—will serve you well.

And if you’re unsure, ask your supplier. A ten-minute conversation can save you a lot of rework down the road. We’re here to make sure the fasteners you pick stay tight until you want them loose.

FAQs

Q1: Can lock nuts be reused?

A: Nylon insert lock nuts can be reused a few times, but their grip weakens with each cycle. Metal lock nuts generally hold up better to reuse.

Q2: Are lock nuts more expensive than standard nuts?

A: Yes, typically by 20–50%, depending on material and coating. But in vibration-prone applications, they can save money on maintenance.

Q3: Do I need a washer with a lock nut?

A: Not always. Serrated flange lock nuts have a built-in washer surface. For nylon insert types, a flat washer can help spread the load and protect softer surfaces.