caTEGORIES

Tags

When to Use Fully Threaded Rods and When to Pick Partially Threaded Studs

Posted: June 19, 2025

Categories: News

Tags: news

Introduction

Fasteners are super important in building and fixing stuff, and knowing the difference between fully threaded rods and partially threaded studs is a big deal. These parts do different jobs in machines, buildings, and big projects. Picking the right one keeps things strong, safe, and working great for a long time.

QEWITCO Fasteners Co., Ltd. is a trusty global supplier of top-notch fasteners. They mix British know-how with great value from the Far East to help with your work needs. With over 30,000 products, including fully threaded rods and partially threaded studs, QEWITCO gives engineers, buyers, and project bosses solid solutions for any job.

Definitions and Types

What is a Fully Threaded Rod?

A fully threaded rod, sometimes called an all-thread rod, has threads all the way along its length. This full threading lets you adjust it easily. It’s awesome for jobs where pulling forces and flexible sizes matter. You’ll see these rods holding up HVAC systems, securing cable trays, or anchoring machines to the ground.

What is a Partially Threaded Stud?

A partially threaded stud only has threads on some parts. The smooth part, called the grip length, gives extra strength against side pushes and helps line things up just right. These studs are great for heavy jobs where keeping things steady and lined up is super key, like holding water pumps, alternators, or other machine parts.

Performance Comparison

Grip Strength (Tensile)

Fully threaded rods are built for super strong grip. Since threads cover the whole rod, they spread pulling forces evenly with lots of contact points. This makes them perfect for hanging stuff or holding things up, especially in building or factory work.

Shear Strength and Alignment

Partially threaded studs are better for jobs needing strength against side pushes. The smooth grip part takes on those forces and keeps parts lined up exactly. This is super important for precise setups or places with lots of shaking, like in big machines.

Typical Applications

When to Use Fully Threaded Rods

- HVAC and piping setups: Great for hanging ducts, cable trays, and pipes.

- Light framing: Easy to adjust sizes for quick building.

- Electrical and telecom gear: Awesome for mounting on walls, ceilings, or cabinets.

- Masonry and concrete anchoring: With special coatings, they fight rust and hold strong.

When to Use Partially Threaded Studs

- Engine and pump setups: Give steady grip without threads getting in the way.

- Heavy machine mounts: Perfect for handling big side loads.

- Car systems: Good for lining up parts that shake or move a lot.

Advantages & Disadvantages

Fully Threaded Rods

Advantages:

- Full threads make them super flexible.

- Easy to cut to the size you need.

- Awesome for strong pulling jobs.

Disadvantages:

- Threads can wear out in side-push situations.

- Might be too much for jobs needing only some threads.

Partially Threaded Studs

Advantages:

- Smooth grip part gives better side strength.

- Keeps things lined up steady in heavy setups.

- Stops threads from breaking under moving loads.

Disadvantages:

- Not as adjustable.

- Might need exact sizes or custom cuts.

Decision-Making Checklist

To pick the right fastener, think about these:

- What kind of load will it hold?

- Pulling = Fully threaded rod.

- Side push = Partially threaded stud.

- Do you need flexible sizes?

- Yes = Fully threaded rod.

- No = Partially threaded stud.

- Is the place rusty or tough?

- Pick coated options from QEWITCO, like zinc-plated or stainless steel, for toughness.

- Need quick tweaks during setup?

- Go for fully threaded rods you can cut to fit.

Material and Coating Considerations

QEWITCO has tons of materials and finishes for all kinds of jobs:

- Carbon Steel: Cheap and strong, great for regular factory use.

- Stainless Steel (A2, A4): Super rust-proof for outside or sea work.

- Brass/Copper Alloys: Awesome for electric flow and rust protection.

- Surface Finishes:

- Bright Zinc Plated (BZP).

- Hot-Dip Galvanized (HDG).

- Zinc Flake and GEOMET for extra rust protection.

With ISO9001 approval, all QEWITCO products get strict checks. You can ask for 3.1 certificates, ISIR, or PPAP papers to prove their quality.

Installation Tips

Torquing and Thread Engagement

- Always use nuts and washers fully to make it super strong.

- Don’t tighten too hard—it can mess up threads or weaken the hold.

Washers and Locking Mechanisms

- Use flat washers to spread out the load.

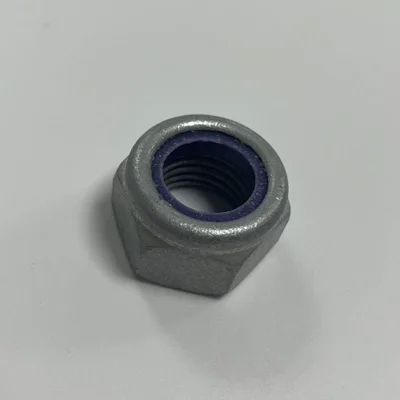

- Nylon insert nuts (DIN 985/982)work great in shaky spots.

- Try patching or locking goo for extra safety.

Conclusion

Choosing between fully threaded rods and partially threaded studs depends on what your job needs. Fully threaded rods are best for pulling strength and size tweaks, while partially threaded studs rock for side strength and exact lining up.

QEWITCO Fasteners has a huge lineup of fasteners made to meet top global rules. With years of know-how and a promise to make customers happy, they’re your go-to for fastening fixes worldwide. Reach out today to check their product list or ask for custom solutions for your project.

FAQs

Q1: What’s the main difference between fully threaded rods and partially threaded studs?

The big difference is how they handle loads. Fully threaded rods are great for pulling strength and adjusting sizes since threads go all the way. Partially threaded studs are better for side forces or precise setups because of their smooth grip part.

Q2: Can I use fully threaded rods instead of partially threaded studs?

Not always. Fully threaded rods are flexible but might not be as strong or steady as partially threaded studs in some machine setups. For important jobs, stick to what the plans say or ask your supplier like QEWITCO for the right swap.

Q3: What coatings should I use for fasteners in outdoor or rusty places?

For outside or wet spots, QEWITCO suggests coatings like Hot-Dip Galvanized (HDG), Zinc Flake, or GEOMET. Stainless steel (A2 or A4 grades) is also super good for long-term rust protection in sea, chemical, or damp places.