caTEGORIES

Tags

Are Metric and Imperial Bolts Interchangeable?

Posted: July 24, 2025

Categories: News

Tags: news

Picking fasteners is tricky. Metric and imperial systems can be hard to choose between. Mixing them can cause big problems. In this article, we’ll explain why they’re different. We’ll show why mixing them is bad. And we’ll give tips on how to switch between them safely.

Understanding the Basics

What Defines Metric vs. Imperial Fasteners?

Metric bolts use millimeters (mm). They have two main features:

- Diameter: An M8 bolt has an 8mm outer diameter.

- Thread Pitch: The space between threads. For example, M8 × 1.25 means 1.25mm between threads.

Imperial bolts use inches. They’re called UNC/UNF or Unified Thread Standard bolts. They have:

- Diameter in inches: Like 1/4″.

- Threads per inch (TPI): For example, 1/4″-20 means 20 threads in one inch.

Metric bolts are common worldwide. They’re used in Europe, Asia, and many places. Imperial bolts are mostly used in the USA and some parts of Canada. They’re also in old machines.

QEWIT supplies both types to over 20 countries. We make sure they fit different rules and needs.

Where Are These Systems Used?

Metric bolts are used in most countries. They’re common in cars, machines, and building work. Imperial bolts are big in the USA. You see them in older equipment or American-made cars. QEWIT helps customers pick the right bolts. We know the standards for different places.

Why Metric and Imperial Bolts Are Not Interchangeable

Thread Profile and Pitch Differences

Metric and imperial bolts might look close in size. But their threads don’t match. For example:

- An M8 × 1.25 bolt has 1.25mm between threads.

- A 5/16″-18 bolt has about 1.41mm between threads (18 TPI).

This small difference messes things up. The threads won’t fit right. They can get stuck or break. This happens because the thread shape and angle are different too.

Fitment Issues and Safety Risks

Sometimes, a bolt might seem to fit. But if the threads don’t line up:

- The bolt won’t hold tight.

- Threads can wear out fast.

- The connection might come loose with shaking.

- In big projects, this can be really bad.

A 2023 study by the National Institute of Standards and Technology (NIST) found that improper fastener use, including mixing metric and imperial bolts, contributed to 15% of mechanical failures in U.S. industrial projects, costing an estimated $500 million annually (Source: NIST Technical Report, 2023).

At QEWIT, we tell clients that close sizes aren’t enough. You need the exact thread type. We use special tools like testers and cameras to check threads. This keeps things safe and strong.

Misconceptions and Common Exceptions

Near-Match Examples That Still Don’t Fit

Some bolts seem like they could work together. For example:

- M6 vs. 1/4″-20.

- M8 × 1.25 vs. 5/16″-18.

But even tiny differences in threads cause problems. Over time, these mismatches break down. They can’t hold up in tough jobs.

Use in Legacy or Hybrid Equipment

In rare cases, old machines might use both types. These are special cases. They often need custom parts like threaded inserts. QEWIT makes these custom parts. We help clients with old or mixed machines. Our team checks each case to find the best fix.

Converting Between Metric and Imperial

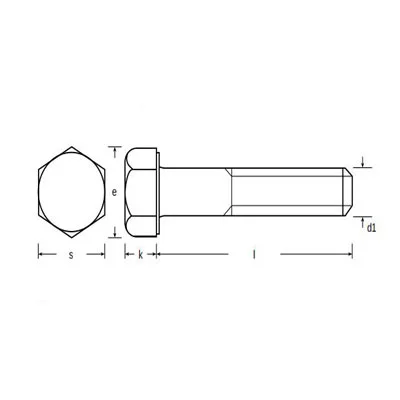

Measurement Tools

You need good tools to measure bolts. We suggest:

- Thread pitch gauge: Checks the space between threads.

- Digital calipers: Measures the diameter.

- TPI indicators: Counts threads per inch for imperial bolts.

QEWIT uses fancy tools like Vickers hardness testers and torsion meters. These check if threads are right and strong. This helps us pick the correct bolt every time.

Sample Conversion Table

Here’s a table to show close sizes. But they don’t work together:

| Metric Size | Closest Imperial Equivalent | Notes |

| M6 × 1.0 | 1/4″-20 | Threads don’t match. |

| M8 × 1.25 | 5/16″-18 | Close size, but not safe. |

| M10 × 1.5 | 3/8″-16 | Pitch difference makes it bad. |

Always check with a thread gauge. Don’t guess sizes.

How to Spot Metric vs. Imperial Bolts

It’s easy to mix up metric and imperial bolts. Here’s how to tell them apart:

- Markings: Metric bolts often have numbers like “8.8” or “10.9” on the head. These show strength. Imperial bolts might have lines, like 3 for Grade 5 or 6 for Grade 8.

- Size Labels: Metric bolts start with “M” (like M8). Imperial bolts use inches (like 1/4″-20).

- Feel: Metric threads feel tighter. Imperial threads feel looser because they’re wider.

QEWIT’s team can help you spot the difference. We use tools to check bolts fast. This saves time and stops mistakes.

Best Practices When Dealing with Different Standards

Stick to One Standard Per Assembly

Use one type of bolt for each project. Mixing metric and imperial causes trouble. It’s hard to fix or replace parts later. QEWIT helps clients keep things simple. We make sure all bolts match the project’s needs.

Use Compatible Fasteners from Trusted Suppliers

Pick a supplier like QEWIT. We know both metric and imperial systems. We offer parts that meet ISO 898, DIN, ANSI, or ASTM standards. Our stock includes:

- DIN 933 Hex Set Screws(Metric).

- UNC/UNF Hex Bolts (Imperial).

- Threaded Inserts for Cross-System Applications.

With over 30,000 SKU lines, QEWIT sends everything in one shipment. This cuts down on delays and mix-ups.

When Conversion Is Inevitable

Sometimes, you have to switch between metric and imperial. This happens with old machines or repairs. Here’s what to do:

- Use adapter nuts, helicoils, or threaded inserts.

- Write down and label all changes clearly.

- Don’t use converted bolts in heavy-duty jobs.

QEWIT makes custom parts like threaded inserts. We can make bolts to your exact needs. This keeps your project safe and strong.

Tips for Avoiding Mix-Ups

Mixing metric and imperial bolts is a common mistake. Here are some tips to avoid it:

- Label Everything: Mark bolts as metric or imperial when you store them.

- Use the Right Tools: Metric bolts need metric wrenches. Imperial bolts need imperial ones. Mixing tools can ruin bolts.

- Check the Manual: Look at your equipment’s guide. It tells you which bolts to use.

- Ask Experts: QEWIT’s team can check your bolts and suggest the right ones.

These steps save time and keep your projects safe. QEWIT offers free advice to help you get it right.

Why Choose QEWIT for Global Fastener Needs

QEWIT started as a British company. We have years of know-how. We mix Western-style service with fast production. We offer:

- Metric and imperial bolts, nuts, and threaded parts.

- Custom parts that meet DIN, ISO, ANSI, and ASTM standards.

- Help with picking the right threads.

- Quick delivery for standards like DIN 934, DIN 931, and UNC Hex Bolts.

Whether you’re a store, a factory, or a builder, QEWIT is your go-to. Our ISO-certified quality and global reach make us a great partner.

Conclusion

Metric and imperial bolts might look alike. But they don’t work together. Mixing them can break equipment or cause safety issues. It can also waste time. Knowing the differences is key. Working with a trusted supplier like QEWIT helps you pick the right bolts.

We make sure you get the best fasteners every time. Trust QEWIT for all your fastener needs.

FAQs

Q1. Can I force a metric bolt into an imperial nut or vice versa?

A: No. Even small differences in threads can hurt both parts. This makes the connection weak or unsafe.

Q2. How do I know if a bolt is metric or imperial?

A: Metric bolts often start with “M” (like M8) and list pitch in millimeters. Imperial bolts use inches and TPI (like 1/4″-20). Use a thread gauge or caliper to check.

Q3. Does QEWIT provide both metric and imperial options?

A: Yes. We have a big range of both systems. Our team helps you pick the right fastener for your market and project.